Página(s): [1]

Calibrador

Lapidart® calibrating machine has an unique design that allows it to shape and calibrate the girdle and the pavilion of gems quickly and accurately just by moving the arm from 90 degrees (for girdle) or 45 (or any other) degrees for pavilion.

Switching a 1mm pass micrometer on the top of the mast it is possible to control the calibrating machine up and down to cut the stone at the required size. Lapidart® calibrating machine has a 18 acrylic cams set in many shapes (1 square, 1 heart, 1 trillion, 4 ovals, 4 pear shapes, 4 rectangular, 3 marquise (no round cam needed, the axis “is” the cam). They are numbered one by one to permit appropriate calibration between width and length (2mm, 3mm, 4mm, 5mm and 6mm differences). The cams are installed easily in the axis’ machine and work like a “key copier” machine. You can, first, preform the girdle, than the pavilion. After faceting and polishing the pavilion, you start preform the crown at the desired angle. It means you can determinate the inclination of the crown and the table size at the same time. It helps a lot when faceting, so the facets to be cut will already be on the right degree position. It’s a piece of cake!

When using the Lapidart® calibrating machine it will not be necessary to preform the stone by free hand perfectly: just saw and preform it roughly, stick the gems’ table on the dop, choose the cam and preform both girdle and pavilion perfectly.

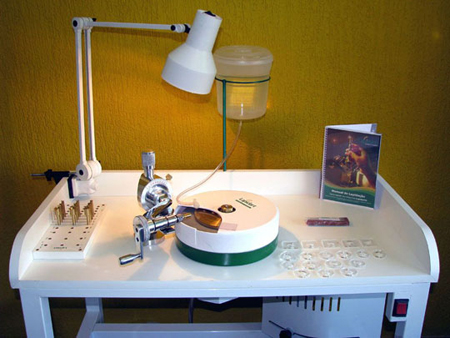

See the main compounds of the Lapidart® Calibrating machine:

1 –Protractor (0 to 90 degrees) built in polished aluminium; stainless steel mast with micrometer at the top; nickel brass arm; cams’ base made from stainless steel; axis and other pieces of the rotating system built in stainless steel; easy and safe plug-in dop device with steel pin-guide; 360 degrees adjustable base with table knob locker (no tool required to adjust the knob locker: just use a special dop that follows the equipment!).

2 - 18 shapes of cams: 1 square, 1 heart, 1 trillion, 4 ovals, 4 pear shapes, 4 rectangular, 3 marquise (no round cam needed).

3 - Industrial bench: built in white painted steel and top made of white wood MDF with mechanical speed control (3 speeds, changed on belts and pulleys). Size: 80 cm x 50 cm x 75 cm.

4 – Internal bivolt dialogic speed control (converter AC 110-220 volts / CC 24 volts) with graduated knob from 0 to 3.500 rpm and permanent torque even in slow speeds. It allows you cut and polish at different speeds in the same machine. Panel with on-off switch button, led; built-in fan; 110-220 v switch button; electrostatic white painting on steel plate. External fuse avoids damages to the equipment caused by voltage oscillations.

5 – Dops: Kit of 12 aluminum dops (4 V, 4 flats, 4 conics), with a dops-support numbered both in mm and inches (complete kit from 2mm to 1’ with 36 dops is available (US$ 160,00).

6 – Lamp: Architect style with pressure claws fixation, for halogen 15w lamp (not included).

7 – Cooling system: Plastic tank with a steel support and a needle drop microregister and flexible hose.

8 – Wax: Used to fix the gems on the dops, the Lapidart wax has high viscosity and avoids the stone comes unfastened during the stone cutting. Its exclusive stick shape facilitates the collage on the dop and avoids wastes.

9 – Calibrating lap: 180 or 260 grid mounted on an extra light aluminium base. You can also choose sintered diamond laps, that last for many years (please ask for models and prices).

10 – Faceting handbook and owner's manual: The step-by-step of cutting and polishing, illustrated with pictures, drawings and diagrams of a standard round brilliant cut (in Portuguese. To be translated soon).

11 – The industrial calibrating, faceting or Kit 3x1 equipment uses a digital speed controller (not shown in this picture) that allows you to range from 500 RPM to 3.750 RPM quickly, just pushing a bottom up or down. It uses a trifasic industrial motor for 127V or 220V, 60Hertz, as required by the client. Very heavy duty equipment, long life and silent motor.

Lapidart Fornitura e Showroom:Rua João Gualberto Filho, 1402, Bairro Sagrada Família, Belo Horizonte, MG, CEP 31035-570.